Buy Plate Heat Exchanger TSC 9950

Plate Heat Exchanger TS 4201

Max Flow Rate: 933 m³/h

Plates Material: AISI 304/316, Titanium

Gaskets: NBR, EPDM, FKM

Energy Recovery: Up to 90%

Product Overview:

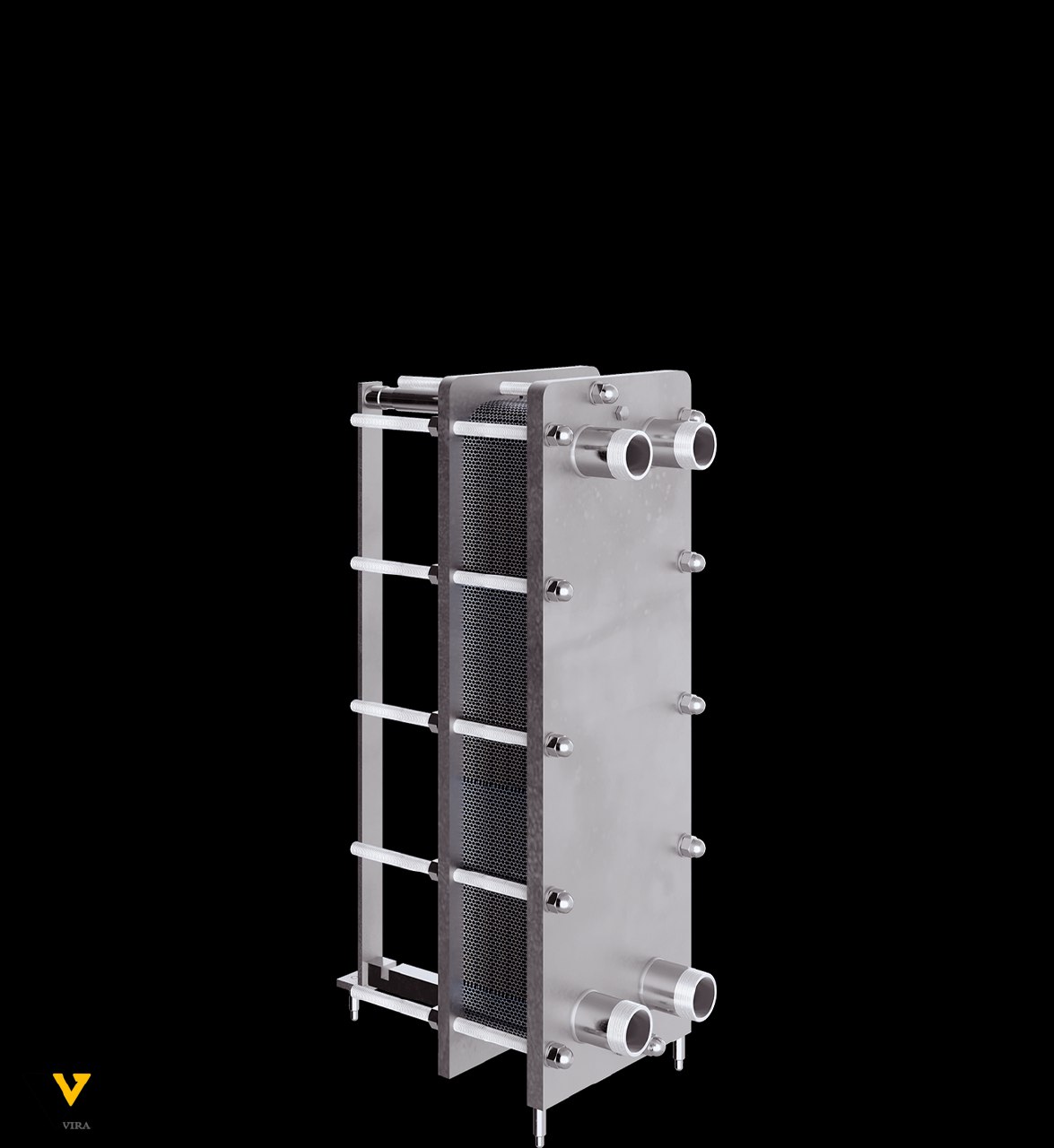

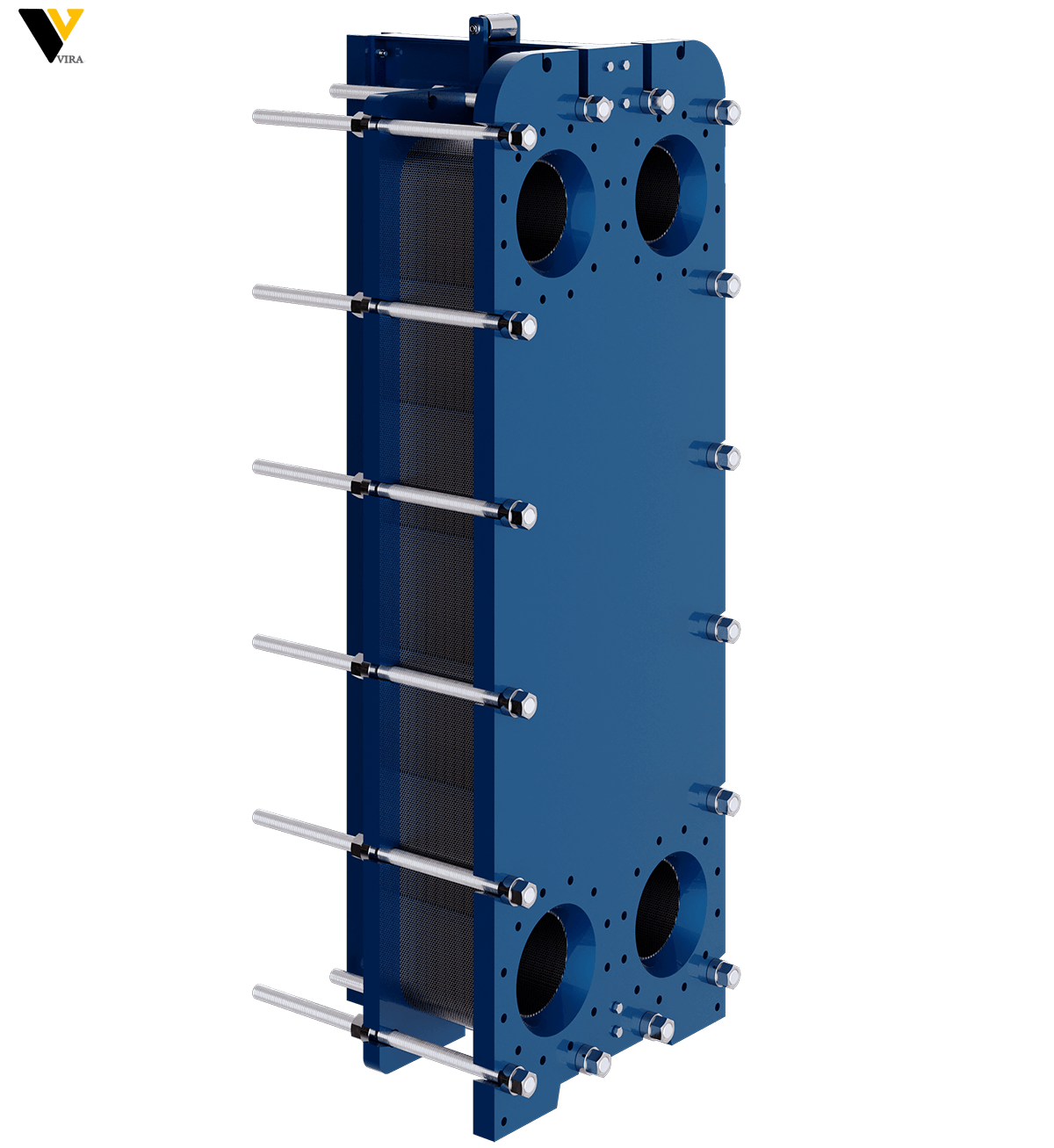

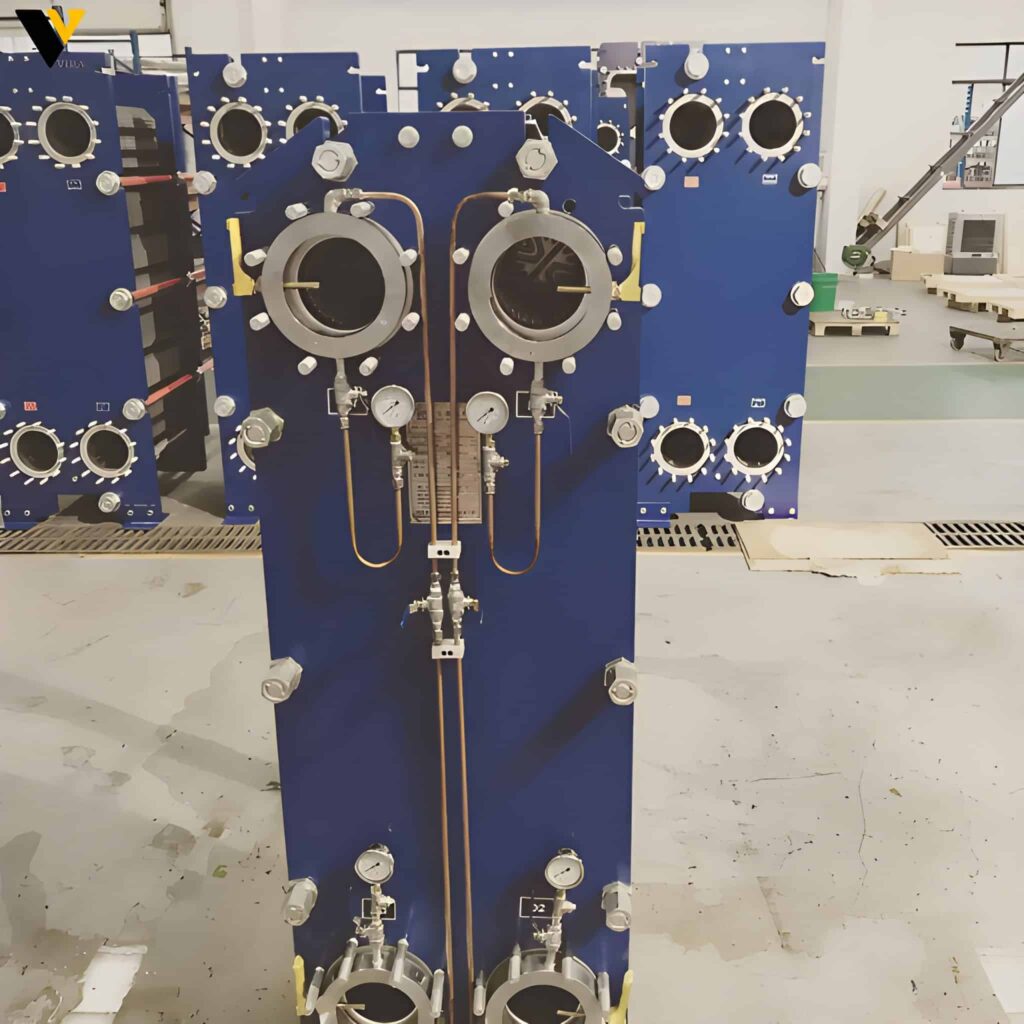

The TSC 9950 Gasketed Plate Heat Exchanger is an advanced thermal solution from Technosystem, featuring corrugated plate technology with gasket sealing system.

This heat exchanger offers inspection and expansion capabilities, manufactured and tested according to PED standards with full customization options.

Technical Specifications TSC 9950:

| Feature | Specification | Details |

|---|---|---|

| Model | TSC 9950 | Gasketed Plate Heat Exchanger |

| Maximum Flow Rate | 933 m³/h | With water as medium |

| Maximum Plates | 389 units | Expandable configuration |

| Operating Pressure | PN10, PN16, PN25 | Multiple pressure ratings |

| Frame Materials | Carbon Steel P355NH, AISI 304L/316L | Painted or stainless options |

| Plate Materials | AISI 304/316, Titanium, SMO 254 | Corrosion-resistant options |

| Gasket Types | NBR, EPDM, FKM | Temperature & chemical compatible |

| Connection Materials | ASTM A193 B7/B8/B8M | High-strength fasteners |

| Applications | Heating, Cooling, Steam, Food fluids | Multi-purpose design |

| Industries | HVAC, Cogeneration, Industrial, District Heating | Wide sector coverage |

| Standards Compliance | PED Certified | European safety standards |

| Customization | Fully Customizable | Application-specific design |

Advanced Engineering Design:

The TSC 9950 incorporates cutting-edge corrugated plate technology that maximizes heat transfer efficiency while minimizing space requirements.

The unique herringbone pattern on each plate creates optimal turbulence, significantly enhancing thermal performance compared to traditional shell-and-tube heat exchangers.

This innovative design achieves heat transfer coefficients 3-5 times higher than conventional alternatives.

The gasketed construction allows complete disassembly for thorough inspection and maintenance.

Unlike welded or brazed units, the TSC 9950 provides 100% access to all heat transfer surfaces, enabling comprehensive cleaning and component replacement without system replacement. This feature proves invaluable in industries requiring strict hygiene standards or dealing with fouling media.

Quality Assurance:

Every TSC 9950 undergoes rigorous testing according to PED standards before shipment.

Pressure testing, leak detection, and performance verification ensure reliable operation from startup. Comprehensive documentation includes material certificates, test records, and operational guidelines.

The manufacturing process incorporates advanced quality control measures including automated welding, precision machining, and statistical process control.

This ensures consistent quality and performance across all units while maintaining competitive pricing.

Conclusion:

The TSC 9950 Gasketed Plate Heat Exchanger represents the optimal solution for demanding thermal applications.

Its combination of advanced engineering, premium materials, and operational flexibility delivers exceptional value across diverse industries.

Whether for new installations or replacement applications, the TSC 9950 provides the performance, reliability, and efficiency modern thermal systems demand.