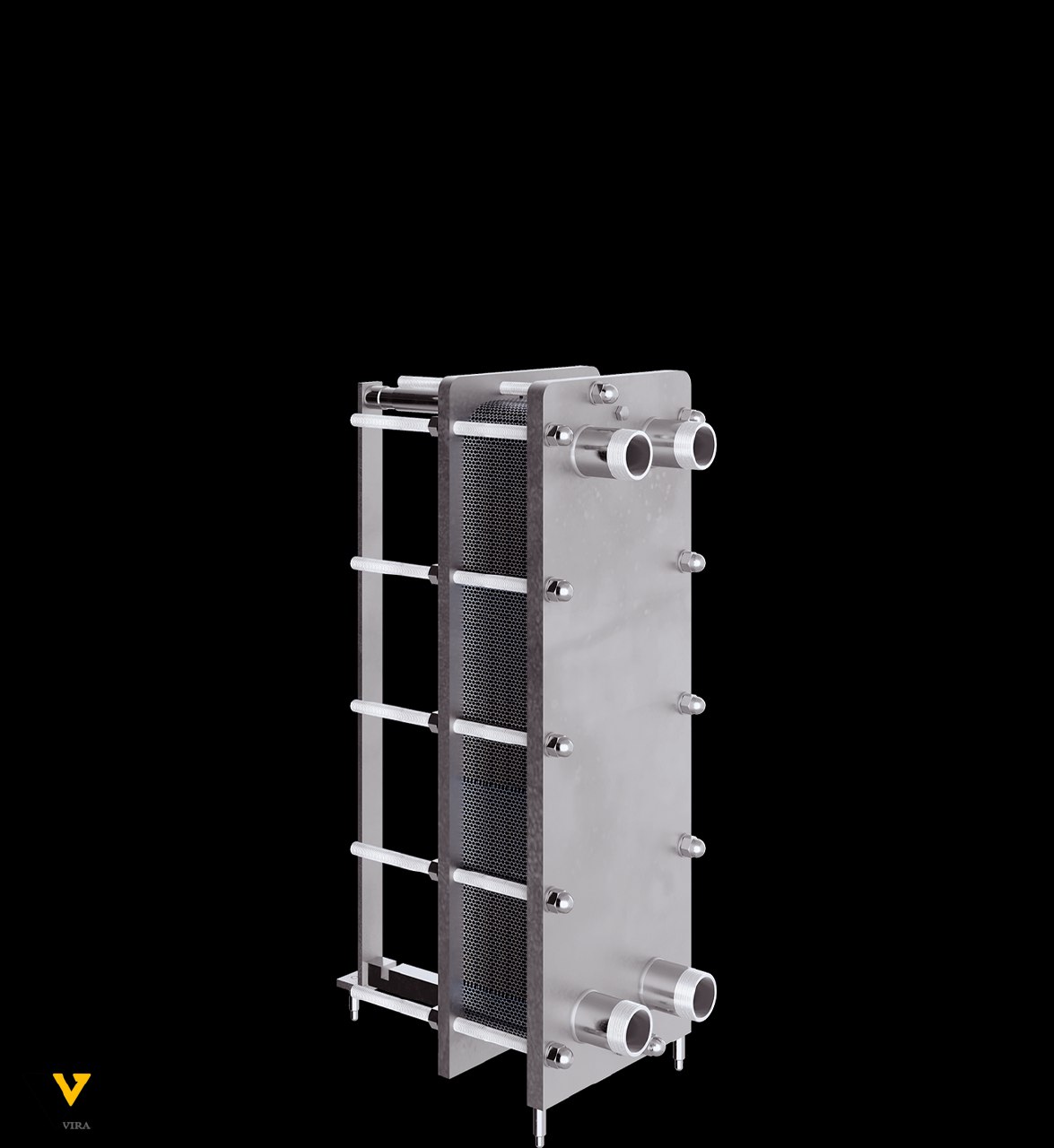

Plate Heat Exchanger TSC 911

Plate Heat Exchanger TSC 4450

Max Flow Rate: 15 m³/h (with water)

Plates Material: AISI 304/316, Titanium

Gaskets: NBR, EPDM, FKM

Energy Recovery: Up to 90%

Product Overview:

The TSC 911 Gasketed Plate Heat Exchanger by Technosystem is a high-performance solution designed for industries that require efficient heating, cooling, and pasteurization processes.

Built and tested in compliance with PED standards, this unit guarantees maximum safety, reliability, and energy efficiency.

Thanks to its gasketed design, the TSC 911 can be easily opened for inspection, cleaning, and expansion (adding plates to increase capacity).

Its flexible configuration and wide range of materials (stainless steel, titanium, SMO 254) make it suitable for demanding applications in both the food industry and broader industrial sectors.

Technical Specifications TSC 911:

| Feature | Description |

|---|---|

| Applications | Heating, cooling, steam usage, food fluids, oils |

| Max flow rate | 15 m³/h (with water) |

| Max number of plates | 159 |

| Chassis | PN10, PN16 (PN25 on request) |

| Frame material | Painted carbon steel P355NH / ASTM A516 Gr.70 |

| Plate material | Stainless steel AISI 304 or AISI 316, Titanium, SMO 254 alloy |

| Gasket materials | NBR, EPDM, FKM |

| Connection materials | Galvanized steel ASTM A193 B7, stainless steel ASTM A193 B8 or B8M |

Applications TSC 911:

Food Industry: pasteurization, cooling, and heating of food fluids and oils

Industrial Sector: heating and cooling of process fluids

HVAC systems: hot water and chilled water circuits

Energy-saving systems: using steam for heating and recovery processes

Benefits of TSC 911:

✅ High thermal efficiency

✅ Compact and space-saving design

✅ Easy maintenance and cleaning

✅ Long service life with corrosion-resistant materials

✅ Flexible plate and gasket selection to fit your exact needs

Frequently Asked Questions:

1. Can the TSC 911 be expanded in the future?

Yes. As a gasketed plate heat exchanger, it allows additional plates to be added to increase capacity.

2. Is it suitable for food-grade applications?

Yes. With FDA-approved gaskets (EPDM, NBR, FKM) and stainless steel plates, it is ideal for the food and beverage industry.

3. What is the maximum flow rate?

The TSC 911 supports up to 15 m³/h with water.

4. Can it be used with steam?

Yes. It is designed to handle steam for heating processes.

5. Which industries benefit most from this model?

Primarily the food industry, but also industrial plants, HVAC systems, and energy recovery processes.

Price & Purchase Information:

At Tivan Mobadel Vira Industries (official supplier of Technosystem heat exchangers in Iran), we provide the TSC 911 model at competitive factory-direct prices. Costs vary depending on:

Plate material (AISI 304, 316, Titanium, SMO 254)

Number of plates required (capacity)

Gasket type (EPDM, NBR, FKM)

👉 For the best price and technical consultation, contact our expert sales team. We ensure fast delivery, after-sales support, and custom configurations tailored to your project.

Conclusion:

The Technosystem TSC 911 Gasketed Plate Heat Exchanger is a reliable, energy-efficient, and flexible solution for both food and industrial applications. With its PED certification, customizable design, and FDA-approved components, it delivers long-term performance and cost savings.

Whether you need it for pasteurization, steam heating, cooling, or process fluids, the TSC 911 is engineered to meet the most demanding operational requirements.

👉 Order now from Tivan Mobadel Vira Industries for the best price, expert support, and guaranteed quality.