Plate Heat Exchanger TS 4201

Plate Heat Exchanger TS 4201

Max Flow Rate: 330 m³/h (tested with water)

Plates Material: Stainless Steel AISI 304

Gaskets: NBR, EPDM, FKM

Energy Recovery: Up to 90%

Product Description:

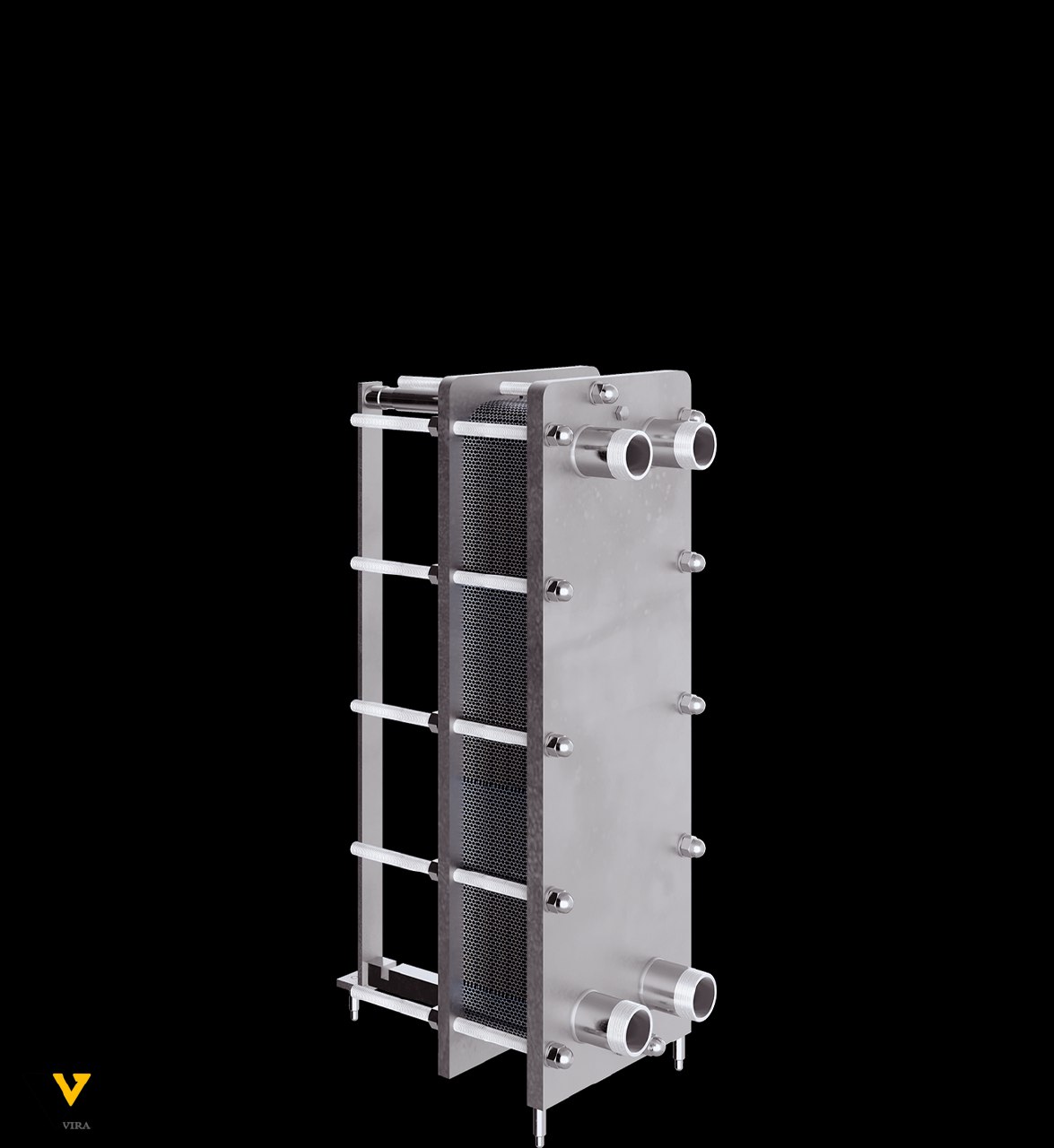

TS 4201 – Smooth Plate Heat Exchanger with Turbulator:

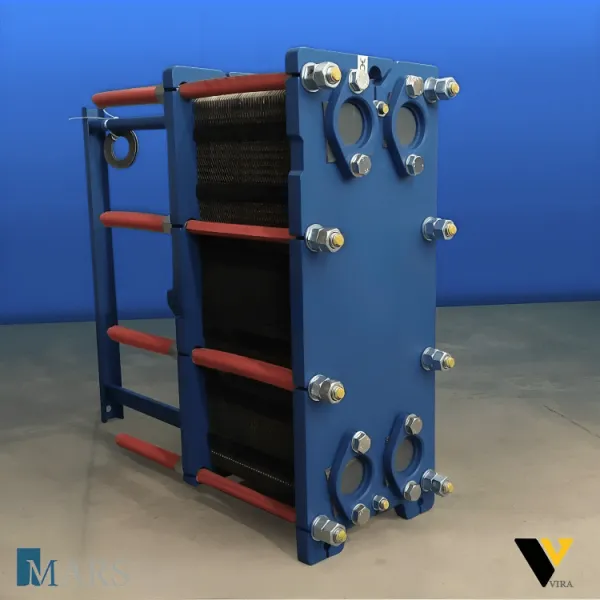

The TS 4201 from Techno System is a cutting-edge smooth plate heat exchanger equipped with a turbulator and gaskets, designed to deliver superior heat transfer performance across demanding applications.

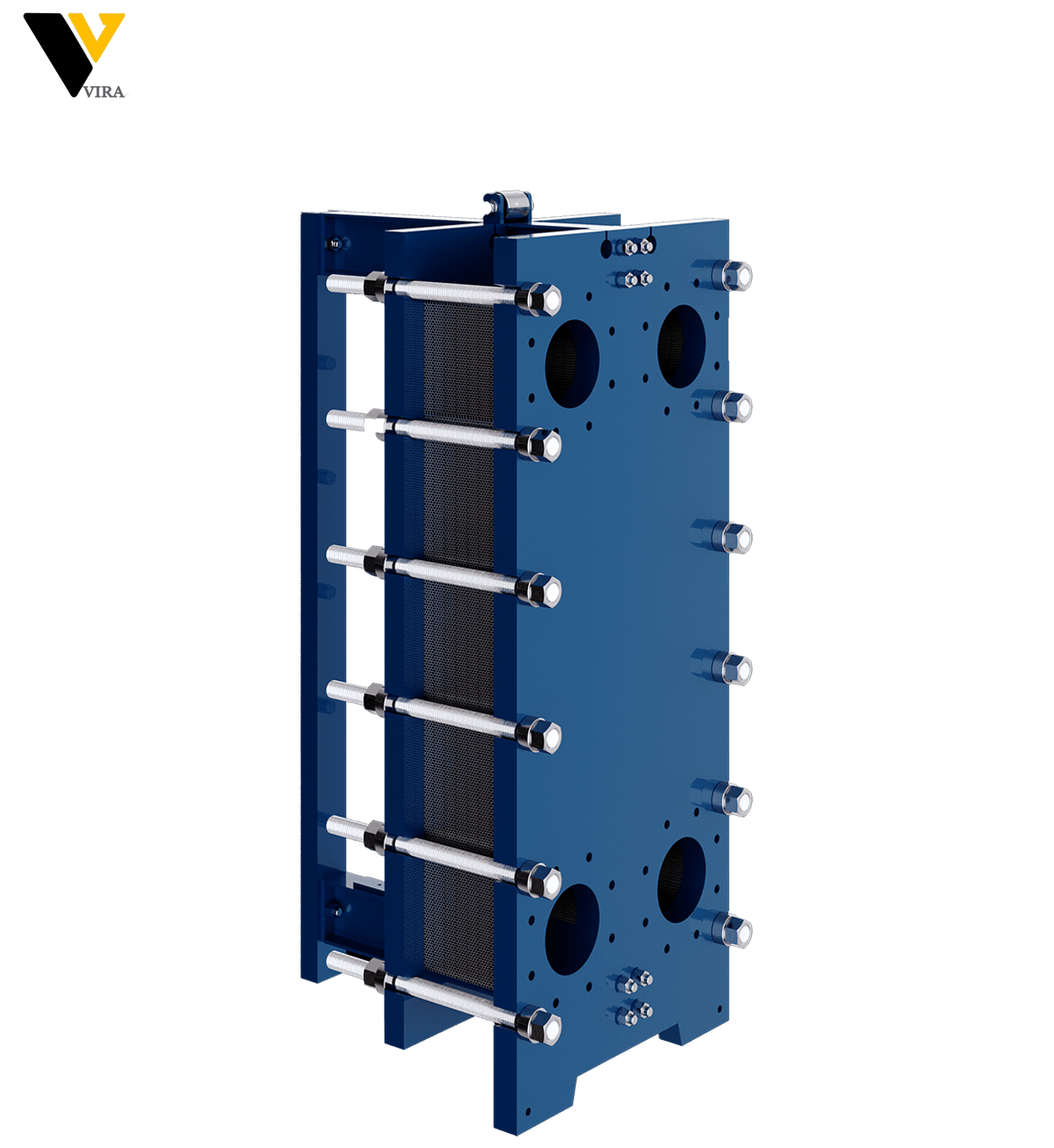

Engineered for inspectability and expandability, this model is built and rigorously tested to meet PED (Pressure Equipment Directive) standards, ensuring compliance and safety.

Its customizable design, high flow capacity, and robust construction make it a standout choice for industries requiring reliable heating, cooling, or steam-based processes.

With rapid delivery options for standard configurations, the TS 4201 is ready to power your operations with minimal lead time.

Versatile Applications:

The TS 4201 is built to handle a wide range of thermal management tasks with precision:

- Heating Systems – Efficiently transfers heat for industrial processes or building HVAC systems.

- Cooling Operations – Provides rapid and consistent cooling for chillers, machinery, or district cooling networks.

- Steam Applications – Designed to withstand high-pressure steam for sterilization or process heating.

- Oil Processing – Compatible with oils, ensuring smooth operation in lubrication or hydraulic systems.

Targeted Sectors:

The TS 4201 is tailored for industries that demand high performance and scalability:

- HVAC – Optimizes temperature control in commercial and residential buildings.

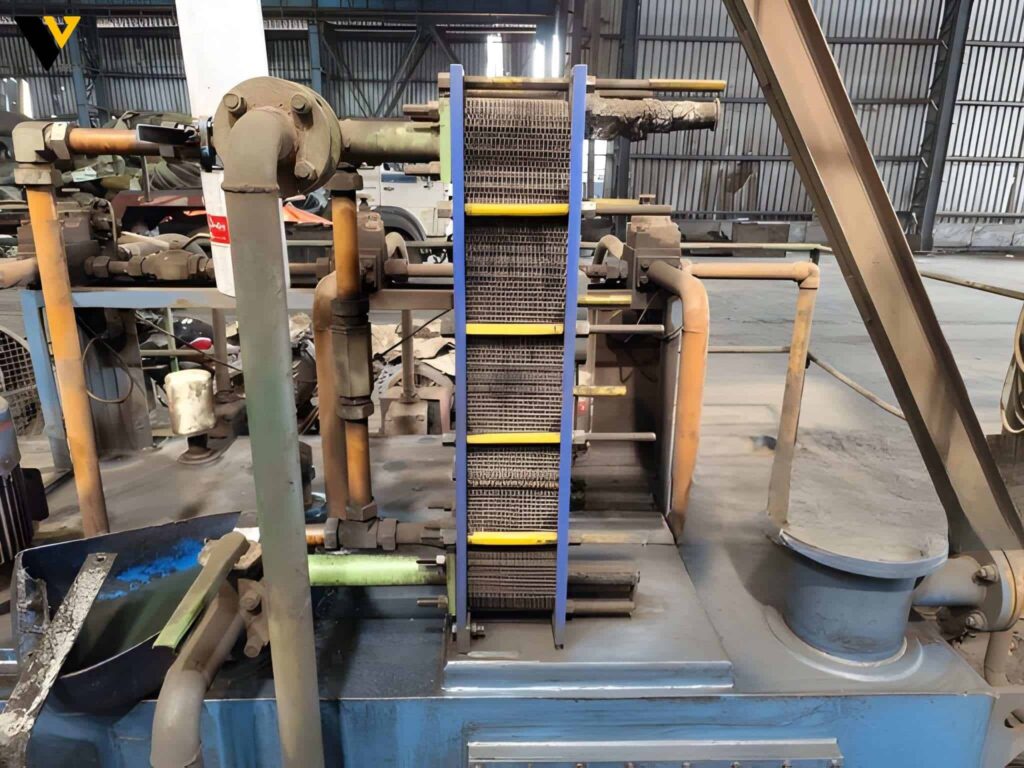

- Industrial – Supports heavy-duty manufacturing, chemical processing, and energy recovery systems.

- District Heating – Facilitates efficient heat distribution from centralized plants to communities.

Detailed Technical Specifications:

| Feature | Details |

|---|---|

| Max Flow Rate | 330 m³/h (tested with water) |

| Max Number of Plates | 335 |

| Pressure Ratings | PN6, PN10 (PN16 available upon request) |

| Chassis Materials | Stainless Steel AISI 304L or AISI 316L |

| Plate Materials | Stainless Steel AISI 304, AISI 316, Titanium |

| Gasket Options | NBR (Nitrile), EPDM, FKM (Viton) |

| Connection Materials | Galvanized Steel ASTM A193 B7 |

| Certification | PED-compliant, Customizable design |

| Design Advantage | Smooth plates with turbulator for enhanced heat transfer |

Key Features and Benefits:

- High Flow Capacity – With a maximum flow rate of 330 m³/h, the TS 4201 is ideal for large-scale applications, ensuring high throughput without compromising efficiency.

- Smooth Plate Technology with Turbulator – The innovative turbulator enhances fluid turbulence, maximizing heat transfer efficiency while maintaining low pressure drops.

- Customizable Configurations – Tailor plate materials, gasket types, and pressure ratings to meet specific operational requirements, from low-pressure HVAC to high-pressure industrial systems.

- Robust Material Options – Choose from corrosion-resistant materials like Titanium or Alloy SMO 254 for aggressive fluids, or cost-effective stainless steel for standard applications.

- Easy Maintenance – Gasketed design allows for quick disassembly, inspection, and cleaning, minimizing downtime and maintenance costs.

- Energy Efficiency – Optimized plate design reduces energy consumption by up to 35% compared to traditional heat exchangers, lowering operational costs.

- Scalable Design – Expandable up to 335 plates, allowing easy upgrades as your system demands grow.

Conclusion:

The TS 4201 smooth plate heat exchanger redefines efficiency and adaptability for high-capacity thermal management. With its innovative turbulator, robust material options, and scalable design, it meets the needs of diverse industries, from HVAC to heavy industrial processes.

Certified to PED standards and backed by Vira Trading Group’s global expertise, the TS 4201 ensures long-term reliability, energy savings, and operational flexibility.

Invest in the TS 4201 today to elevate your system’s performance and stay ahead in a competitive market.

Frequently Asked Questions (FAQ):

Q1: What makes the TS 4201 suitable for high-flow applications?

Its ability to handle up to 330 m³/h and support up to 335 plates ensures it can manage large volumes while maintaining efficient heat transfer.

Q2: Can it handle corrosive or high-temperature fluids?

Yes, with options for Titanium or Alloy SMO 254 plates and FKM gaskets, it’s built for corrosive fluids and temperatures up to 180°C (depending on gasket selection).

Q3: How does the turbulator improve performance?

The turbulator creates controlled turbulence in the fluid flow, enhancing heat transfer efficiency without significantly increasing pressure loss.

Q4: Is it compliant with international standards?

The TS 4201 is fully PED-certified, ensuring safety and reliability for global markets.

Q5: How quickly can I receive a unit?

Standard configurations are available within days, while custom orders are processed efficiently through Vira Trading Group.

Pricing and Purchase Options:

Pricing for the TS 4201 varies based on:

- Selected plate and gasket materials

- Number of plates (up to 335)

- Pressure rating (PN10, PN16, or PN25)

- Customization requirements

For a detailed quote, volume discounts, or expedited shipping, contact Vira Trading Group, the exclusive exporter. They provide tailored solutions, including installation support and spare parts.

📧 Email: info@Vira-hu.com

📞 Phone: +36204735352

🌐 Website: www.viraphe.com