Graphitized Petroleum Coke

- admin

- ferroalloys

Executive Summary:

We are a Eurasia‑based manufacturer and supplier of Graphitized Petroleum Coke (GPC), delivering high‑purity carbon materials tailored to metallurgical and industrial applications.

Our production focuses on consistent quality control, low sulfur levels, and optimized particle sizing, ensuring predictable performance in steelmaking and foundry operations.

By leveraging regional production advantages and efficient supply chains across Eurasia, we are able to offer competitive pricing without compromising technical standards.

Our materials are developed to meet the requirements of customers seeking reliable carbon solutions with stable specifications and dependable availability.

For a detailed technical reference and material overview, please visit our main resource:

https://ferrosilicon.co/graphitized-petroleum-coke-overview/

What Is Graphitized Petroleum Coke (GPC)?

Graphitized Petroleum Coke (GPC) is a high‑purity carbon material produced by heat‑treating calcined petroleum coke at ultra‑high temperatures (typically 2,800–3,000 °C).

This process rearranges the carbon structure into a highly ordered graphite lattice, significantly improving electrical conductivity, thermal stability, and carbon absorption efficiency.

GPC is primarily used in steelmaking and foundry operations as a carbon raiser, where precise control of carbon content is critical.

Compared to conventional carbon materials, GPC offers very high fixed carbon, extremely low sulfur, and minimal ash, making it suitable for applications with strict chemical and metallurgical requirements.

From a production perspective, the performance of GPC depends on feedstock selection, graphitization temperature control, and post‑processing size classification.

Typical specifications include fixed carbon levels above 99 %, sulfur below 0.05 %, and controlled particle size ranges to ensure predictable dissolution behavior in molten metal.

Due to these characteristics, GPC is widely preferred in applications where chemical purity, consistency, and repeatable performance outweigh cost‑driven alternatives.

Manufacturing Process of Graphitized Petroleum Coke (GPC):

The manufacturing process of Graphitized Petroleum Coke (GPC) is a high‑temperature carbon transformation sequence designed to convert calcined petroleum coke into a structurally ordered, high‑purity graphitic material.

Product performance is directly linked to feedstock quality, thermal treatment parameters, and size control throughout the process.

1. Feedstock Selection and Preparation

GPC production begins with the selection of low‑impurity calcined petroleum coke (CPC). Key parameters evaluated at this stage include sulfur content, ash level, and initial carbon structure.

Consistent feedstock quality is critical for achieving uniform graphitization results.

2. High‑Temperature Graphitization

The prepared CPC is exposed to ultra‑high temperatures (approximately 2,800–3,000 °C) in specialized electric or Acheson‑type furnaces.

At these temperatures, disordered carbon atoms reorganize into a crystalline graphite lattice, significantly improving electrical conductivity and carbon assimilation.

3. Structural Transformation and Purification

During graphitization, residual volatile matter is removed, and sulfur content is further reduced. This step enhances fixed carbon levels and minimizes unwanted impurities that can negatively affect metallurgical performance.

4. Cooling and Stabilization

After graphitization, controlled cooling is applied to stabilize the carbon structure and prevent internal stress formation. Proper cooling ensures predictable physical and chemical behavior in downstream applications.

5. Crushing, Sieving, and Size Classification

The final step involves mechanical processing to achieve defined particle size ranges (e.g., 1–5 mm, 1–3 mm, or customized fractions). Accurate size control plays a crucial role in dissolution kinetics when GPC is used as a carbon raiser in molten metal.

Manufacturing Process of Graphitized Petroleum Coke (GPC):

Pricing of Graphitized Petroleum Coke (GPC) in the Eurasian market reflects a combination of material quality, processing intensity, and logistics structure, rather than a fixed list price.

The ranges below represent typical market indications for industrial‑grade GPC used in steelmaking and foundry applications. Final pricing is normally determined after technical specification review.

| GPC Grade Characteristics | Fixed Carbon (%) | Sulfur (%) | Typical Size | Indicative Price Range* |

|---|---|---|---|---|

| Standard Industrial Grade | ≥ 98.5 | ≤ 0.05 | 1–5 mm | USD 750 – 900 / MT |

| Low‑Sulfur Grade | ≥ 99.0 | ≤ 0.03 | 1–5 mm | USD 900 – 1,050 / MT |

| High‑Purity Grade | ≥ 99.2 | ≤ 0.02 | Customized | USD 1,050 – 1,250 / MT |

*Price ranges are indicative for the Eurasian market in 2025 and may vary based on order volume, particle size distribution, and delivery terms.

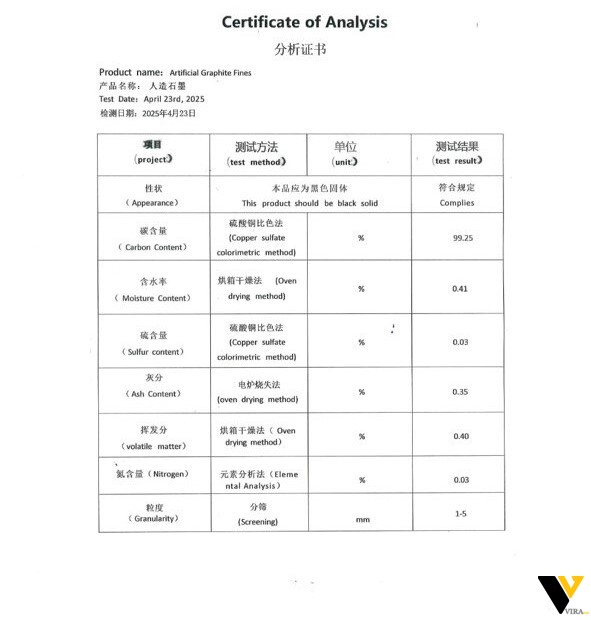

Technical Properties and Chemical Specifications:

The technical performance of Graphitized Petroleum Coke (GPC) is determined by its chemical purity, carbon structure, and particle size distribution.

The properties below represent a typical analysis of high‑purity GPC commonly used in steelmaking and foundry applications where controlled carbon addition and low impurity levels are required.

Typical Chemical Analysis of GPC

| Parameter | Test Method | Unit | Typical Value |

|---|---|---|---|

| Fixed Carbon | Copper sulfate colorimetric method | % | 99.25 |

| Sulfur (S) | Copper sulfate colorimetric method | % | 0.03 |

| Moisture (H₂O) | Oven drying method | % | 0.41 |

| Ash Content | Oven drying method | % | 0.35 |

| Volatile Matter (VM) | Oven drying method | % | 0.40 |

| Nitrogen (N) | Elemental analysis | % | 0.03 |

| Particle Size | Screening | mm | 1–5 |

Typical Chemical Analysis of GPC

- High fixed carbon (>99%) ensures efficient and predictable carbon pickup in molten steel.

- Low sulfur levels (≤0.03%) minimize residual sulfur introduction, critical for quality steel grades.

- Low ash and volatile matter reduce slag formation and unwanted reactions during melting.

- Controlled particle size (1–5 mm) provides stable dissolution kinetics and uniform carbon distribution.

These parameters make high‑purity GPC especially suitable for precision carbon adjustment, where chemical consistency and repeatable performance are prioritized over volume‑driven alternatives.

All data shown is representative and provided for technical evaluation purposes only.

Applications of GPC in Metallurgical Industries:

Graphitized Petroleum Coke (GPC) is widely used in metallurgical industries as a high‑purity carbon source where controlled chemistry and stable performance are required.

Its low impurity levels and highly ordered carbon structure make it suitable for processes sensitive to sulfur, ash, and volatile matter.

Steelmaking (Carbon Raiser)

In steel production, GPC is primarily applied as a carbon raiser for precise carbon adjustment in molten steel. Its high fixed carbon content and low sulfur level enable efficient carbon pickup with minimal impact on steel cleanliness.

Controlled particle size distributions improve dissolution behavior and reduce carbon loss during charging.

Foundry Applications

In foundry operations, GPC is used to regulate carbon content in cast iron and specialty alloys.

Compared to conventional carbon sources, GPC provides more predictable metallurgical performance, particularly in applications requiring low nitrogen and sulfur control to maintain cast structure quality.

Metallurgy with Ferroalloys

GPC is often utilized alongside ferroalloys to fine‑tune carbon levels without altering the primary alloy chemistry. This approach is common in secondary metallurgy, where maintaining tight compositional tolerances is critical.

Performance‑Driven Applications

Due to its purity and structural stability, GPC is selected in operations where:

- Sulfur pickup must be strictly limited

- Carbon absorption efficiency is critical

- Process repeatability is required across multiple heats

Frequently Asked Questions:

1. What is the main technical difference between GPC and CPC?

The primary difference lies in the carbon structure. GPC is fully graphitized, resulting in a highly ordered crystalline structure, while CPC remains semi‑crystalline. This structural difference directly affects carbon dissolution rate, pickup efficiency, and process stability.

2. Why is GPC preferred in low‑sulfur steelmaking applications?

GPC typically contains ≤0.03% sulfur, making it suitable for applications where sulfur control is critical. CPC grades often contain higher sulfur levels, which may limit their use in quality‑sensitive steel grades.

3. Does GPC provide better carbon pickup than CPC?

Yes. Due to its graphitized structure, GPC generally offers higher and more predictable carbon pickup efficiency, especially in ladle and secondary metallurgy operations.

4. Is CPC still used in modern steel plants despite lower purity?

Yes. CPC is widely used for bulk carbon addition in cost‑sensitive operations where sulfur tolerance is higher and ultra‑tight chemistry control is not required.

5. Can GPC and CPC be used together in one process?

In many practical operations, CPC is used as a baseline carbon source, while GPC is added later to fine‑tune final carbon levels without introducing additional impurities.

6. How does particle size affect the performance of GPC compared to CPC?

Smaller and controlled particle sizes (e.g., 1–5 mm) improve dissolution kinetics. GPC with uniform sizing shows more consistent behavior than CPC, which may have wider size and quality variability.

7. Is GPC required for all steel grades?

No. GPC is typically selected for high‑quality, low‑impurity steels or applications requiring repeatability. Standard construction grades may not require GPC if CPC quality is acceptable.

8. Are chemical values for GPC guaranteed or indicative?

Published values are generally indicative and based on typical COA data. Actual specifications depend on feedstock, graphitization process, and batch‑specific analysis.

Conclusion:

Graphitized Petroleum Coke (GPC) and Calcined Petroleum Coke (CPC) serve distinct roles in metallurgical processes and should not be viewed as interchangeable materials.

While both function as carbon sources, their structural characteristics, impurity profiles, and operational behavior lead to materially different outcomes in steelmaking and foundry applications.

GPC, with its highly ordered carbon structure, very low sulfur, and predictable carbon pickup, is primarily utilized for precision carbon adjustment in applications where chemistry control, cleanliness, and repeatability are critical.

Its use is technically justified in quality‑sensitive steels, secondary metallurgy, and operations where impurity margins are narrow.

CPC, by contrast, remains a cost‑effective solution for bulk carbon addition where sulfur tolerance is higher and ultra‑tight compositional control is not required.

In many industrial settings, CPC fulfills the base carbon requirement efficiently, while GPC is reserved for final chemistry correction.

From an operational standpoint, optimal performance is often achieved through application‑driven material selection, rather than blanket substitution.

Understanding the interaction between carbon structure, particle size, and process conditions allows metallurgical plants to balance performance, cost, and risk across different production scenarios.

📞 Contact Direct